Resistant to the Environment

The vulcanisation process means that the material differs from all thermoplastic products, in that its properties are not affected by varying temperatures. The product is chemically stable and always returns to its original dimensions after stretching.

The cross-linked molecular structure gives EPDM and Butyl rubber their unique properties. Ageing or changes in characteristics are negligible despite decades of exposure to the atmosphere, sunlight, UV radiation, chemical fallout, water or major temperature fluctuations.

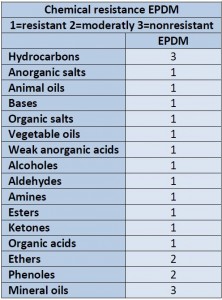

Chemically Stable

EPDM and Butyl rubber contain no plasticisers or additives which can evaporate or be washed out over the years. The strength and elasticity of the membrane remain practically unchanged for decades, without shrinkage, brittleness, melting or cracking. The membrane is equally elastic, regardless of whether the temperature is -30°C or +120°C.

BASIC PROPERTIES OF EPDM Rubber

EPDM RUBBER compared to several common geomembrane materials*

*note that Southland only fabricates liners using EPDM and Butyl rubber materials. Most of the other materials in the below table are ‘plastics’. The main difference between a plastic and a rubber is – a plastic will not return to its original shape after stretching but will permanently deform. Rubbers bounce back and return to their original shape even after being stretched up to 300%